Download Full Colour Chart

Colourcrete Colour Hardener is a pre-mixed, dry-shake, coloured concrete hardener. It is used for colouring and hardening freshly placed concrete which achives a surface that is substantially harder and more wear-resistant than regular concrete. Colourcrete Colour Hardener is a blend of specially selected and graded aggregates, cements, additives and synthetic oxide pigments that produces a brilliant, streak free, wear-resistant surface.

Features

- Conditions and hardens the concrete surface

- Excellent abrasion and wear resistance

- Reduces porosity

- Increases surface density

- High pigment quality

- Streak-free finish

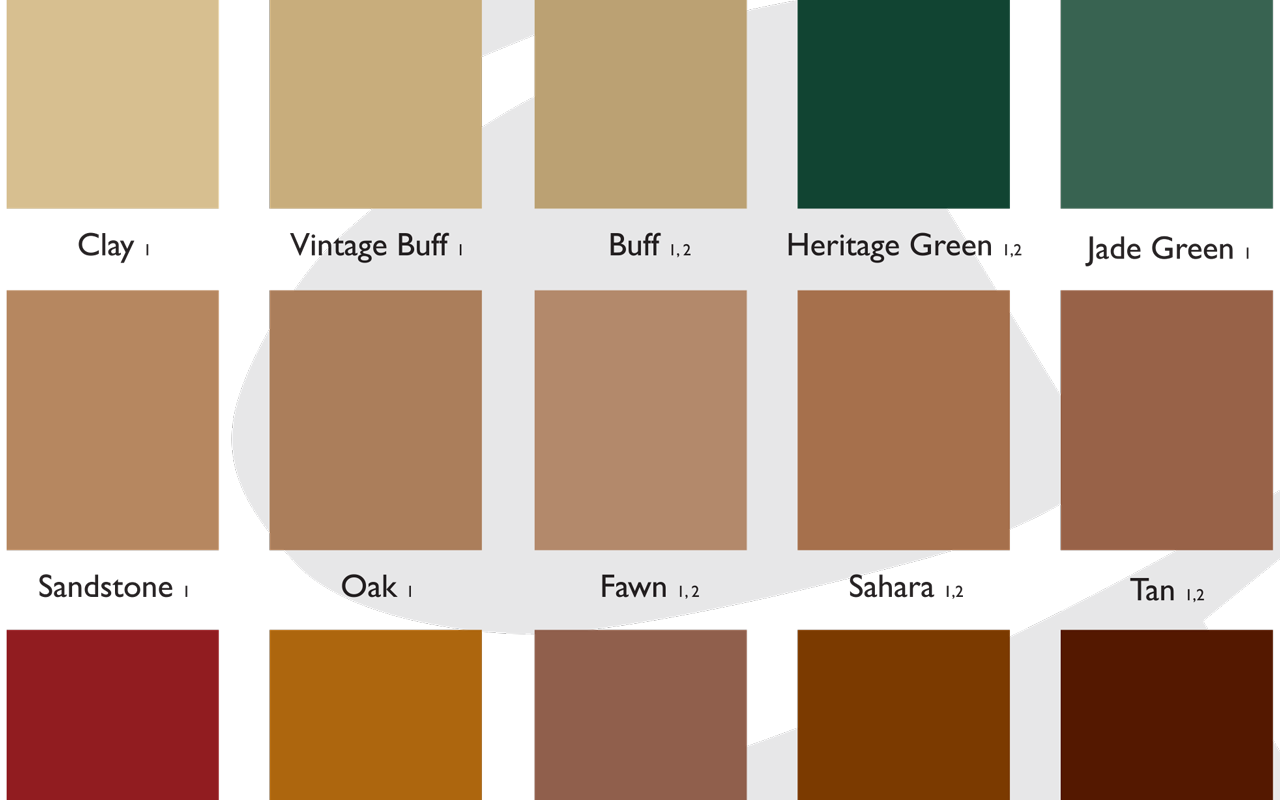

- 22 custom colours available

Application

Colourcrete Colour Hardener is broadcast evenly to the surface of the freshly placed concrete after surface bleed water has ceased or been when removed. In order to develop proper bond and adequate density, the moisture for wetting the hardener must come from the concrete substrate. Colourcrete Colour Hardener is usually applied in two applications, with two-thirds being applied in the first application and one-third in the second application

After the first application, the surface is floated. Apply the second perpendicular to the first application in a uniform manner. Float in and trowel to the final desired finish.

Colourcrete Colour hardener may also be used as a “plaster mix” when doing steps or other vertical surfaces. During the final set stage of the concrete, add only enough water to the Colourcrete Colour hardener to achieve a workable consistency, then apply the plaster mix to the vertical surface and finish as normal.

Coverage Guidelines

- Coverage requirements vary according to the intended use and colour

- Dark colours 2.0-2.5kg per square metre

- Light colours 3.0-4.5kg per square metre

- Commercial / Industrial applications may require slightly heavier application rates

Maintenance

It is highly recommended to develop and follow a routine maintenance schedule for all coloured concrete so that it will maintain a top quality appearance. Every 18 to 36 months, coloured concrete installations should be inspected, cleaned and resealed as required by volume and intensity of traffic. The need will depend on a number of factors including traffic conditions, geographical location and weather.